Formwork Plywood: A Cost-Benefit Analysis for Builders

Formwork plywood is a crucial component in the construction industry, particularly for builders involved in concrete formwork projects. Its importance cannot be overstated, as the choice of formwork material can significantly impact both the cost and efficiency of a building project. In this article, we will delve into the various aspects of formwork plywood, examining its features, costs, benefits, and comparisons with other materials. By the end, you will have a comprehensive understanding of formwork plywood and be better equipped to make an informed decision for your building project.

Understanding Formwork Plywood

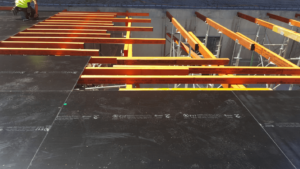

Before delving into the cost and benefits of formwork plywood or formply, let's start by understanding its basics. Formwork plywood is a type of engineered wood that is specifically designed for use in concrete formwork. It is primarily used to create molds or formworks into which concrete is poured and allowed to set. These formworks provide structural support and shape to the concrete, allowing it to retain its desired form as it cures.

The Basics of Formwork Plywood

Formwork plywood is made by bonding several layers of thin wood veneers together using adhesive. The layers are stacked in a cross-grain arrangement, which imparts strength and dimensional stability to the plywood. This construction method ensures that the plywood can withstand the pressure exerted by wet concrete without warping or deforming. It is also designed to be reusable, making it a cost-effective choice in the long run. Click here to learn about selecting the right formwork plywood for various construction types.

Key Features of Formwork Plywood

Formwork plywood possesses several key features that make it an ideal choice for builders:

Strength

Formwork plywood has excellent load-bearing capacity, allowing it to support the weight of wet concrete without compromising its structural integrity.

Dimensional Stability

The cross-grain arrangement of the veneers ensures that formwork plywood remains stable and resistant to warping even when exposed to moisture.

Resistance to Chemicals

Formwork plywood is treated with preservatives to enhance its resistance to chemicals present in concrete, ensuring its longevity.

Reusability

Compared to other formwork materials, such as steel or plastic, formwork plywood can be reused multiple times, reducing project costs and environmental impact.

Additionally, formwork plywood offers versatility in terms of size and thickness. It can be manufactured in various dimensions to suit different project requirements. This flexibility allows builders to create formworks of different shapes and sizes, accommodating unique architectural designs and structural elements.

Furthermore, formwork plywood is known for its ease of handling and installation. Its lightweight nature makes it easier to transport and maneuver on construction sites, reducing labor costs and improving overall efficiency. The plywood panels can be easily cut and shaped to fit specific formwork configurations, ensuring a precise and snug fit.

Moreover, formwork plywood is compatible with various formwork systems, including traditional timber formwork, modular formwork, and engineered formwork systems. This compatibility allows builders to seamlessly integrate formwork plywood into their preferred construction methods, ensuring a smooth and efficient workflow.

In conclusion, formwork plywood is a reliable and cost-effective solution for concrete formwork. Its strength, dimensional stability, resistance to chemicals, and reusability make it an ideal choice for builders looking to achieve high-quality and durable concrete structures. With its versatility, ease of handling, and compatibility with various formwork systems, formwork plywood offers a practical and efficient solution for construction projects of all scales.

The Cost Aspect of Formwork Plywood

Cost plays a crucial role in the decision-making process for any builder. Let's examine the cost considerations associated with formwork plywood.

When delving into the realm of formwork plywood, it's essential to understand the nuanced layers that contribute to its overall cost-effectiveness. Beyond the initial purchase and installation expenses, there are additional facets that shape the financial landscape of utilizing this versatile material in construction projects.

Initial Purchase and Installation Costs

Formwork plywood is initially more affordable than alternative materials like steel. Its lower upfront cost makes it an attractive option for builders, especially when considering large-scale projects with extensive formwork requirements. Additionally, the installation process for formwork plywood is relatively simple, reducing labor costs and construction time.

However, the financial allure of formwork plywood extends beyond the mere comparison of upfront expenditures. Its lightweight nature not only simplifies transportation and handling but also contributes to cost savings in terms of logistical operations. This aspect is particularly advantageous in projects where time is of the essence, as swift and efficient material handling can lead to substantial cost reductions in the overall project budget.

Maintenance and Replacement Expenses

In the long run, formwork plywood proves to be cost-effective due to its reusability. Although it requires maintenance to ensure its longevity, the costs associated with upkeep are minimal compared to the expenses of purchasing new formwork materials for each project. Regular inspections, cleaning, and applying suitable release agents are key maintenance practices that can extend the lifespan of formwork plywood.

Moreover, the sustainability of formwork plywood lies not only in its ability to withstand multiple reuse cycles but also in its eco-friendly characteristics. As a renewable resource, plywood aligns with environmentally conscious construction practices, offering a greener alternative to traditional formwork materials. This eco-friendly attribute not only contributes to cost savings in terms of waste management and disposal but also enhances the overall sustainability profile of construction projects utilizing formwork plywood.

Occasionally, portions of formwork plywood may need replacement due to wear and tear or damage. However, these replacement costs are significantly lower compared to the overall cost savings achieved through multiple reuse cycles.

The Benefit Side of Formwork Plywood

While cost considerations form a significant aspect of any builder's decision, it is equally important to evaluate the benefits offered by formwork plywood. Let's explore some of these advantages.

Durability and Longevity

Formwork plywood is engineered to withstand the rigors of construction sites and repetitive use. Its strength and resistance to warping ensure that it maintains its structural integrity even under challenging conditions. Properly maintained formwork plywood can last for several years, reducing the need for frequent replacements and saving builders both time and money.

Moreover, the durability of formwork plywood contributes to a safer work environment. Its robust nature provides stability during concrete pouring and prevents accidents that may arise from using weaker materials. This reliability translates to enhanced productivity on the construction site, as workers can focus on their tasks without concerns about the integrity of the formwork.

Efficiency and Versatility

Formwork plywood is known for its ease of use and versatility. Its lightweight nature makes it easy to handle and transport. It can be easily cut, drilled, and shaped to fit various formwork requirements, enabling builders to create customized molds easily. The dimensional stability of formwork plywood also ensures consistent results in terms of shape and form, leading to efficient concrete placement and curing.

Furthermore, the versatility of formwork plywood extends to its reusability. After a project is completed, the plywood can be cleaned, refurbished, and stored for future use. This sustainability aspect not only reduces waste but also proves cost-effective in the long run, as the same formwork plywood can be utilized for multiple construction projects, providing a high return on investment for builders.

Comparing Formwork Plywood with Other Materials

While formwork plywood offers significant benefits, it is essential to compare it with alternative materials to make an informed decision for your project. Let's consider how formwork plywood fares against two commonly used materials in the construction industry: steel and plastic.

Formwork plywood is a versatile and cost-effective material widely used in construction projects for its strength and durability. Its smooth surface allows for easy concrete pouring and finishing, resulting in high-quality concrete structures. In addition to its structural benefits, formwork plywood is also environmentally friendly, as it can be reused multiple times, reducing waste and overall project costs.

Formwork Plywood vs. Steel

Steel is renowned for its strength and durability. However, it is also significantly more expensive than formwork plywood. Additionally, steel formwork requires specialized equipment and skilled labor for installation and dismantling, increasing project costs. While steel may be suitable for specific applications requiring extraordinary load-bearing capabilities, formwork plywood remains a cost-effective choice for most building projects.

Furthermore, formwork plywood offers better insulation properties than steel, helping regulate temperature and moisture levels during the concrete curing process. This can result in improved concrete quality and reduced energy costs over the building's lifespan.

Formwork Plywood vs. Plastic

Plastic formwork is lightweight and offers excellent flexibility. However, its limited reusability compared to formwork plywood makes it less cost-effective in the long run. Plastic formwork is also prone to warping and deformation under significant loads, which can result in inconsistent concrete shapes and compromised structural integrity. Formwork plywood, with its superior durability and dimensional stability, outperforms plastic in terms of reliability and overall cost savings.

Moreover, formwork plywood provides better support for vertical concrete placements, ensuring uniformity and strength in the structure. Its ability to withstand high pressure without deformation makes it a preferred choice for projects where concrete integrity is paramount, such as high-rise buildings and bridges.

Making the Right Choice for Your Building Project

Choosing the right formwork material for your building project requires a careful assessment of your project needs and budget constraints. Here are some essential considerations:

Assessing Your Project Needs

Evaluate the specific requirements of your project, such as the desired concrete shape, load-bearing capacity, and durability. Consider the complexity of your formwork design and the number of reuse cycles necessary. Formwork plywood is suitable for a wide range of applications, including vertical and horizontal formworks, slabs, beams, and columns.

Evaluating Your Budget Constraints

Budget constraints play a significant role in material selection. While formwork plywood offers cost savings in the long run, consider the upfront costs and the scale of your project. If your project requires extraordinary load-bearing capabilities or if you have a limited budget, steel or alternative formwork systems may be worth considering.

By carefully assessing your project needs and budget constraints, you will be able to make an informed decision regarding formwork plywood. Its remarkable strength, dimensional stability, reusability, and cost-effectiveness make it a preferred choice for many builders. Incorporating formwork plywood into your construction projects can help optimize costs while ensuring efficient and reliable concrete formwork.

Furthermore, when considering formwork materials, it is crucial to think about the environmental impact of your choice. Formwork plywood, known for its sustainability and eco-friendly properties, can contribute to green building practices. By opting for formwork plywood sourced from responsibly managed forests or utilizing recycled materials, you can align your construction project with environmentally conscious principles.

Exploring Formwork Innovation

As technology advances, new formwork solutions continue to emerge in the construction industry. Innovations such as prefabricated formwork systems and 3D-printed formwork elements offer increased efficiency and precision in concrete shaping. These cutting-edge formwork technologies not only streamline the construction process but also open up possibilities for intricate and customized designs.

Other resources: How a Buyers Agent Can Assist in Navigating Perth’s Real Estate Market