May 2024

Selecting the Right Formwork Plywood for Various Construction Types

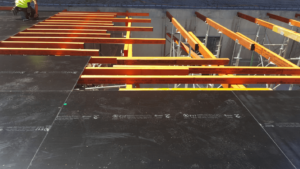

Formwork plywood is an essential component in the construction industry, providing structural support and stability during the building process. It plays a crucial role in ensuring the integrity and durability of structures. However, with numerous options available, selecting the right formwork plywood can be a daunting task. In this article, we will explore the basics […]

Formwork Plywood: A Cost-Benefit Analysis for Builders

Formwork plywood is a crucial component in the construction industry, particularly for builders involved in concrete formwork projects. Its importance cannot be overstated, as the choice of formwork material can significantly impact both the cost and efficiency of a building project. In this article, we will delve into the various aspects of formwork plywood, examining […]